Ръждясването на скобите обикновено не се причинява единствено от „пръски вода върху тях“, а по-скоро от комбинирания ефект на множество фактори:

1. Корозия в околната среда (най-честа причина)

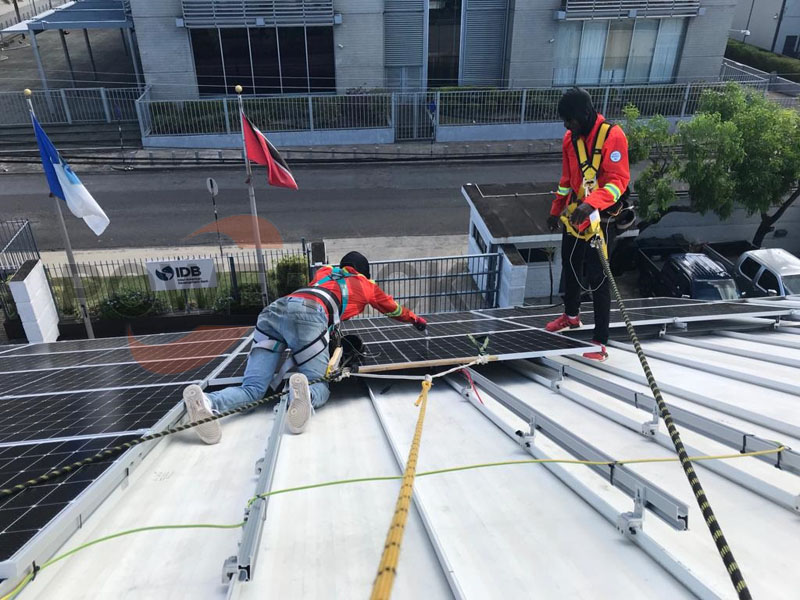

Скоби за монтаж на покриваса по-податливи на фактори на околната среда, отколкото наземните.

Влага и застояла вода: Покривите често натрупват вода или от стрехите им капе дъждовна вода. Продължителната влага създава идеална среда за корозия на метала.

Корозия от солена мъгла: Ако живеете близо до брега, солена почва или индустриални зони (кисели/алкални газове), солите и химикалите във въздуха значително ускоряват окисляването на метала, което води до бърза ръждясване на опорите.

Температурни колебания и UV лъчение: Ежедневните температурни колебания – горещи дни и студени нощи – могат да напукат антикорозионното покритие върху опорните повърхности. UV лъчението ускорява разграждането на покритието. След като защитният слой се повреди, откритият метал ръждясва.

2. Щети по строителството (пренебрегнати детайли)

Често ръждата не се дължи на лошо качество на скобите, а по-скоро на „незначителни пропуски“ по време на монтажа.

Повреди на покритието от пробиване/рязане: При пробиване на отвори или рязане на метал по време на монтаж, всяко увреждане на покритието (оголване на стоманата) ще доведе до „червена ръжда“. Това е най-критичният проблем, тъй като откритата стомана е директно изложена на въздух и корозира изключително бързо.

Цинков слой е откъснат: Ако слънчева носеща конструкцияпретърпява удари по време на транспортиране или монтаж, които премахват повърхностното цинково покритие (слой против ръжда), откритата стомана ще ръждяса бързо.

3. Несъответствие между дизайна и материалите

Контактна корозия: Ако скобата (или болтовете) са поцинковани и използвате крепежни елементи от неръждаема стомана, директният контакт между тези два метала предизвиква електрохимична реакция. Това води до корозия на цинковото покритие, оставяйки след себе си червена ръжда.

Неподходящ избор на материал: В силно корозивни среди (като крайбрежни райони), използването на обикновени стоманени скоби (горещо поцинковани) води до много кратък живот и склонност към ръжда.

Практически съвети за избор на стойки

Първо, помислете за околната среда:

Крайбрежни райони/солено-алкални земи → ZAM е най-добрият избор.

Стандартни градски покриви → Алуминиевата сплав е едновременно лека и икономична.

Обърнете внимание на детайлите на монтажа:

Ако е необходимо пробиване по време на монтажа, уверете се, че пробитата скоба е обработена с антикорозионна боя или антикорозионно масло. Неспазването на това може да причини локализирано ръждясване, което ще повлияе на цялостния експлоатационен живот.

Избягвайте използването на болтове, изработени от различни материали (напр. болтове от неръждаема стомана в директен контакт с поцинковани скоби), за да предотвратите контактна корозия.

Поддръжка и грижи:

Редовно проверявайте скобите, особено точките на свързване. Ако се появят петна от ръжда, отстранете ги своевременно (почистете ръждата и нанесете отново боя против ръжда). Не чакайте ръждясалата зона да се разшири, преди да извършите ремонт.